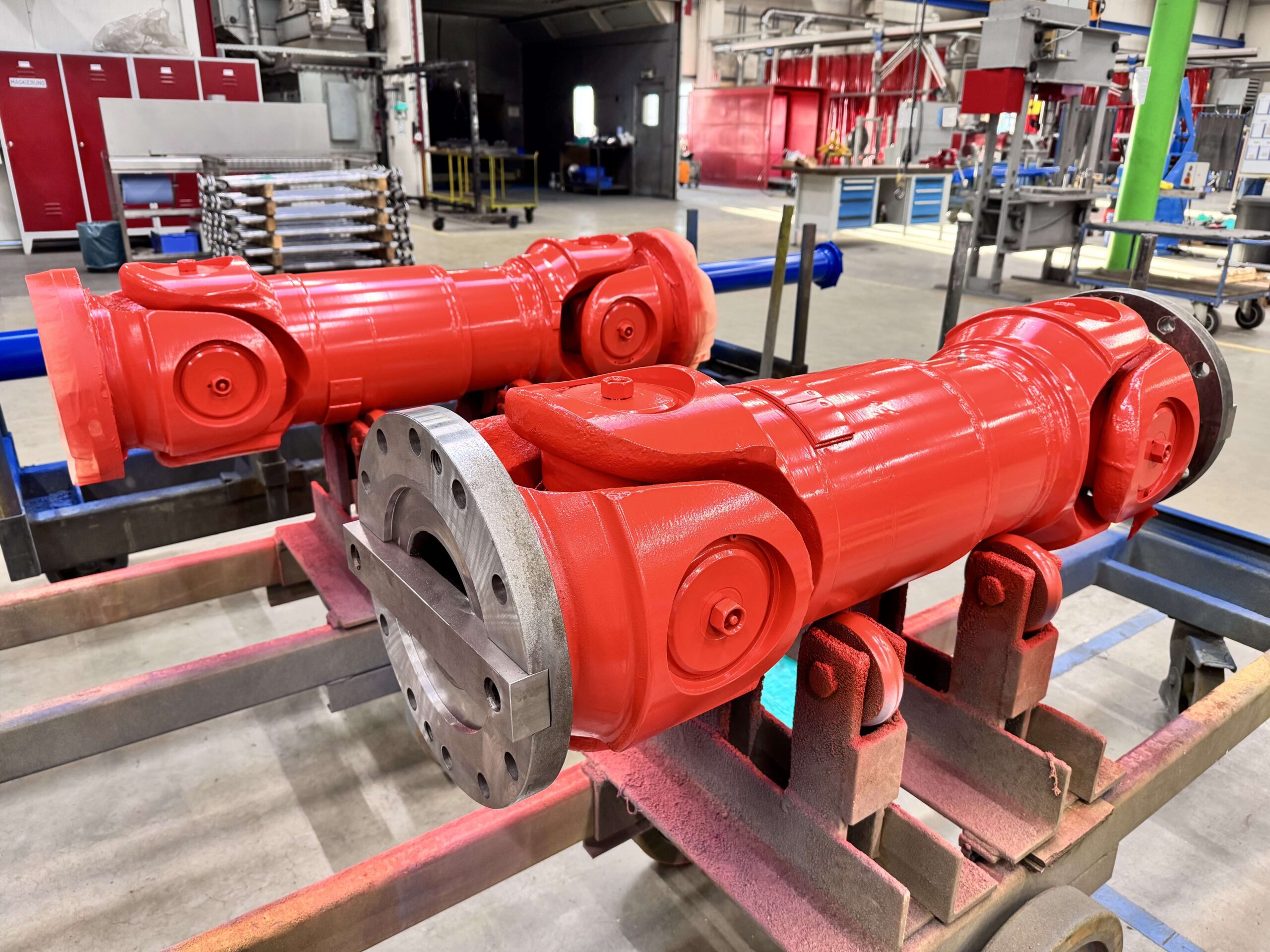

We at Wichmann GmbH recently delivered several drive shafts for sewage treatment plants to WD Klärtechnik GmbH. The shafts drive the scrapers in the clarification tanks – a central component of water purification.

Scrapers ensure that sludge deposited at the bottom of the tank is continuously pushed together and removed. Only with reliable drive components such as our specially manufactured drive shafts can this process be made effective and trouble-free.

Project highlights

- Area of application: Scraper drive in a sewage tank

- Environment: Highly corrosive, humid chemical environment

- Challenge: Protection of the shaft surface against aggressive substances

- Solution: C4 coating as reliable corrosion protection

Thanks to our precise coating process, we can supply drive shafts in C4 design or with customer-specific special coatings. This ensures that our drive components for sewage treatment plants offer maximum service life and reliability even under the toughest conditions.

We combine engineering expertise, high-quality materials, and precise manufacturing to provide solutions for scraper drives and other critical applications.